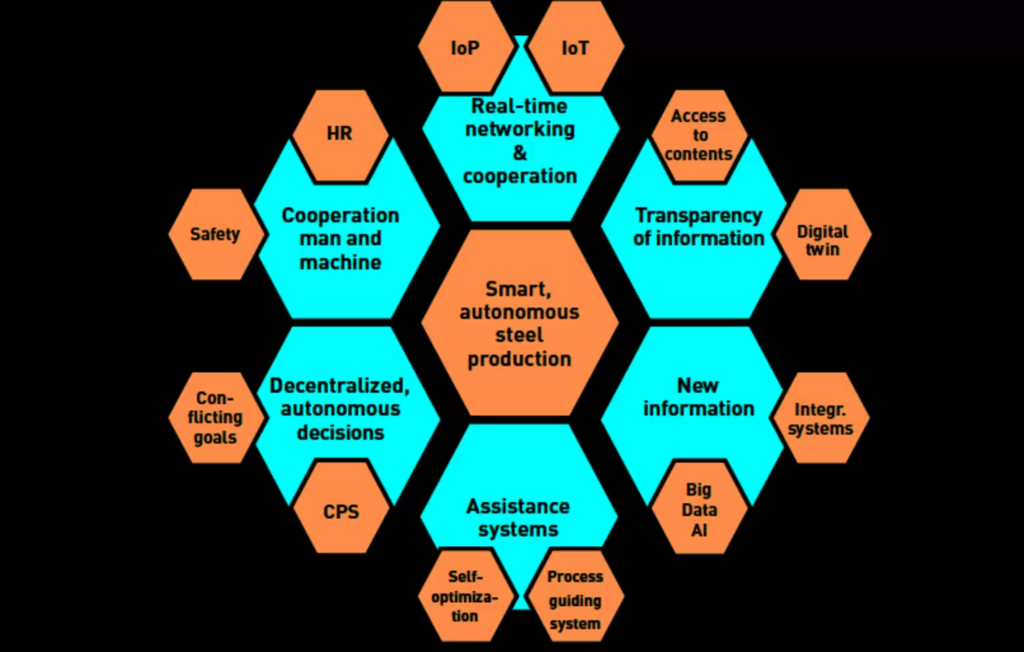

As global demand for metals surges—driven by infrastructure development, renewable energy projects, and automotive advancements—the need for innovation is more pressing than ever. Digital transformation is no longer a choice; it’s a necessity for survival and growth in a competitive global landscape. Real-world examples show that embracing digital tools is key to maintaining operational efficiency, improving decision-making, and ensuring long-term sustainability.

Nucor Corporation’s Success with Digital Tools

A prime example of this shift is Nucor Corporation, one of the largest steel producers in the United States. By integrating AI-powered data analytics and automation into its operations, Nucor has optimized production processes, improved energy efficiency, and reduced costs. This use of digital tools has enabled Nucor to minimize downtime, streamline operations, and enhance product quality, demonstrating how essential digital transformation is for staying competitive in the industry.

1. Enhancing Operational Efficiency

Traditionally, the metal industry has relied on manual processes for production scheduling, inventory management, and quality control. While effective in the past, these methods are increasingly inefficient in today’s fast-paced market. By adopting digital tools like AI and automation, companies can streamline operations, reduce waste, and increase output.

For instance, ArcelorMittal, the world’s largest steelmaker, has implemented IoT sensors in its manufacturing facilities to monitor equipment performance in real-time. This has allowed the company to predict maintenance needs, avoid costly breakdowns, and improve overall productivity. The ability to operate more efficiently translates into significant cost savings and improved market positioning, proving that digital transformation can no longer be overlooked.

2. Data-Driven Decision Making for Competitive Advantage

The metal industry generates vast amounts of data across the supply chain, from raw material sourcing to product distribution. However, much of this valuable information remains underutilized due to outdated systems and siloed processes. Digital transformation enables companies to harness the power of data for more informed decision-making.

A great example is US Steel, which has integrated AI-driven analytics to optimize its supply chain management. By analyzing data from its mills, the company can predict market demand, adjust production schedules, and make more strategic pricing decisions. This data-driven approach has allowed US Steel to minimize risks, reduce operational inefficiencies, and stay agile in a fluctuating market. Harnessing data in this way is essential for companies that want to remain competitive in an increasingly data-driven world.

3. Revolutionizing Quality Control

Product quality is crucial in the metal industry, particularly for sectors like aerospace, automotive, and construction, where safety and precision are paramount. Traditional quality control measures, often involving manual inspections, are prone to human error and inefficiency.

Novelis, a leader in aluminum production, has embraced machine learning to automate its quality control processes. By using AI to detect defects in real-time during production, Novelis has drastically reduced waste and ensured higher-quality output. Automated quality control systems not only lower costs but also build trust with clients who expect the highest standards. Companies that leverage these technologies will be better positioned to meet rising customer expectations for both quality and efficiency.

4. Ensuring Compliance and Traceability

The regulatory landscape for the metal industry is becoming more complex, with increased scrutiny around environmental, labor, and safety standards. Ensuring compliance can be challenging without the right systems in place. Digital transformation offers enhanced traceability and transparency, making it easier to meet regulatory requirements.

Rio Tinto, a major player in the global metals market, has adopted blockchain technology to track the ethical sourcing of raw materials. By using blockchain, Rio Tinto ensures that its materials are responsibly sourced and that all processes comply with industry regulations. This not only helps the company avoid legal risks but also strengthens its reputation as a sustainable and ethical producer. In an era where transparency is paramount, digital tools that enhance traceability are indispensable.

5. Promoting Sustainability and Energy Efficiency

As the world shifts toward more sustainable practices, the metal industry faces increasing pressure to reduce its carbon footprint. Digital transformation is a critical tool for achieving sustainability goals while maintaining profitability.

For example, AK Steel (now part of Cleveland-Cliffs) has implemented AI-driven energy management systems to monitor and optimize energy use across its facilities. These systems identify inefficiencies in real-time, allowing the company to make adjustments that reduce both energy consumption and greenhouse gas emissions. This has helped AK Steel meet strict environmental standards while also cutting operational costs. The ability to align sustainability with profitability is one of the most compelling reasons why digital transformation is essential for the metal industry.

6. Adapting to Market Demands with Agility

The metals market is increasingly volatile, with frequent fluctuations in demand, raw material shortages, and changing customer preferences. Companies need to be able to adapt quickly to these changes to remain competitive.

Alcoa, a major aluminum producer, has adopted digital twin technology to simulate different production scenarios and forecast market trends. This allows the company to adjust its production processes on the fly, ensuring it can meet shifting customer demands without significant disruptions. Digital twins give Alcoa the flexibility to respond to market changes faster than competitors, demonstrating how digital transformation can give companies an edge in an unpredictable marketplace.

7. Rising Competitive Pressure

Digital transformation is not just an advantage—it’s a necessity to remain competitive. Many global leaders in the metal industry are already embracing digital tools, leaving those who lag behind at a significant disadvantage.

Steel Dynamics, Inc. (SDI), one of the largest steel producers in the U.S., has invested heavily in automation and robotics to streamline its steel production processes. These digital advancements have allowed SDI to reduce labor costs, increase production capacity, and improve safety, making it one of the most efficient players in the industry. For U.S. metal companies, keeping up with digital innovation is essential to avoid being left behind by more agile competitors.

The benefits of digital transformation—ranging from operational efficiency and enhanced quality control to sustainability and compliance—are too significant to ignore. Companies that embrace digital tools and strategies will thrive, while those that hesitate risk falling behind in an increasingly competitive global market.

Real-life examples from industry leaders like Nucor, ArcelorMittal, and US Steel prove that digital transformation is not just a trend—it’s the future of the metal industry. For companies ready to take the plunge, the time to act is now.