For manufacturers striving to maintain quality excellence and meet global standards, ISO 9001:2015 remains the benchmark for building trust and consistency in product delivery. At the heart of this compliance journey lies the need for reliable documentation, accurate testing records, and controlled processes. This is where COA (Certificate of Analysis) automation becomes a game-changer—especially when integrated into Quality Management System (QMS) software.

Why COA Matters in ISO Compliance

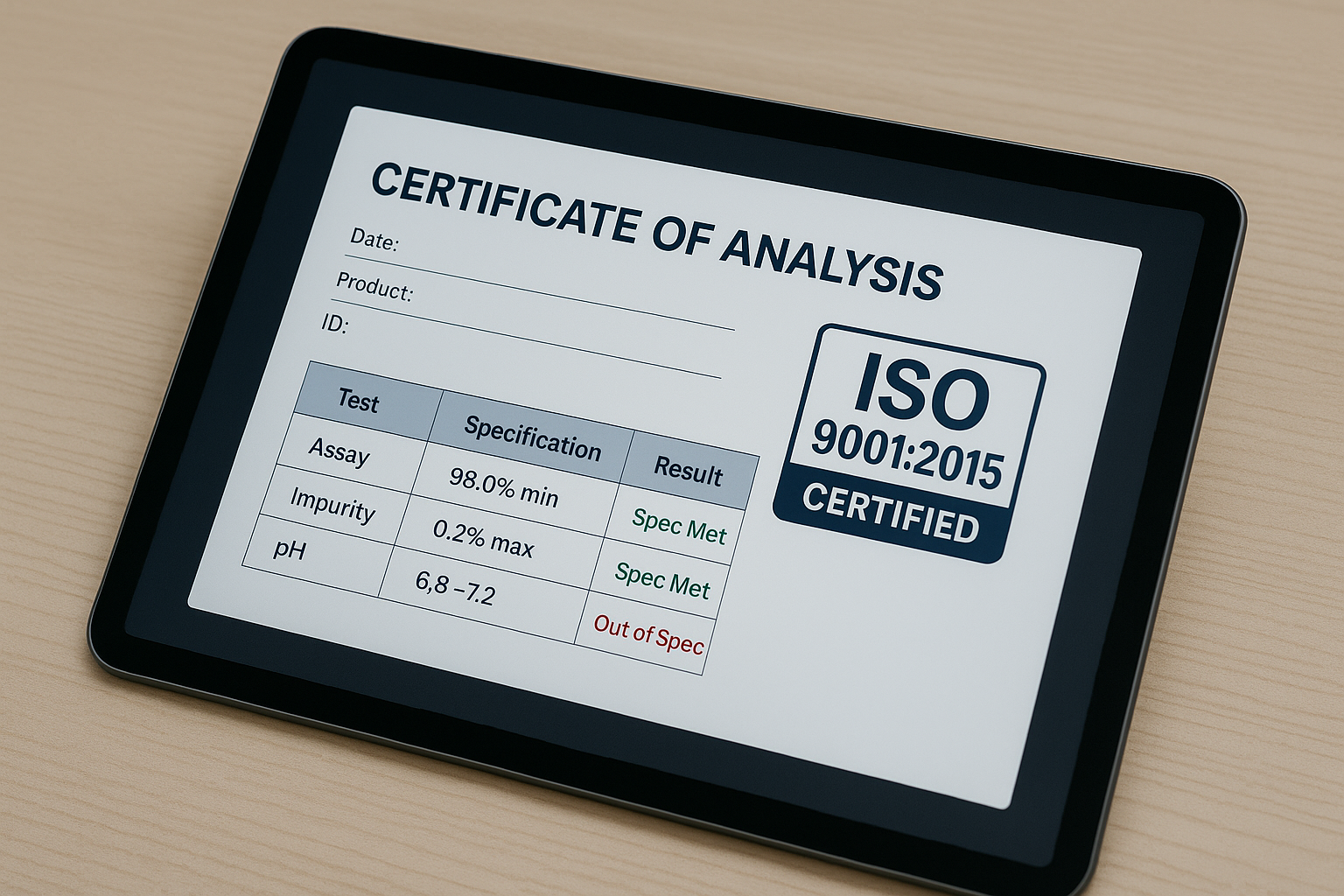

A Certificate of Analysis is a critical document that certifies a product’s compliance with predefined specifications, such as chemical composition, mechanical properties, or microbiological content. In industries like pharmaceuticals, chemicals, metals, and food processing, COAs are not just quality markers—they are regulatory necessities.

Yet, many organizations still rely on manual data entry and fragmented systems to manage these certificates, leading to inconsistencies, delays, and compliance risks.

COA Automation: A Perfect Fit for ISO 9001

Let’s explore how COA automation directly supports the key clauses of ISO 9001:2015, transforming your QMS software into a proactive compliance engine.

1. Evidence-Based Decision Making (Clause 9.1)

ISO 9001 calls for data-driven quality decisions. COA automation ensures that test results are accurately captured from labs or supplier systems using OCR and AI tools. The result? Reliable data sets that allow quality teams to take informed decisions with full traceability.

2. Control of Documented Information (Clause 7.5)

Maintaining version-controlled, accessible, and secure documentation is a requirement. Automated COAs are digitally stored within the QMS, indexed by batch or supplier, and available at a click—removing the chaos of paper trails and misplaced files.

3. Operational Control (Clause 8.5)

Quality assurance depends on releasing only compliant batches. Automated COAs link directly to product specifications and flag out-of-spec results in real time, preventing faulty shipments and ensuring product integrity.

4. Customer Focus (Clause 5.1.2)

When customers demand timely and accurate documentation, COA automation delivers. It enables fast generation of tailored COAs per customer specs, enhancing transparency and building trust.

5. Risk-Based Thinking (Clause 6.1)

Manual COA workflows introduce errors and slow response times. Automation mitigates these risks by enforcing data validation rules, reducing human error, and offering early warnings for non-conformities.

6. Continual Improvement (Clause 10.3)

Automated COAs feed valuable quality trends into your QMS. With the right analytics, businesses can detect recurring issues, improve supplier performance, and optimize manufacturing processes—all aligning with ISO’s focus on continuous improvement.

A Real-World Example

Consider a pharmaceutical manufacturer managing hundreds of raw material lots weekly. With COA automation integrated into their QMS, each incoming batch is automatically verified against specifications. Deviations trigger non-conformance workflows, while compliant batches generate instant COA documents for customer and regulatory records. The result? Faster release cycles, zero data-entry errors, and audit readiness 24/7.

Achieving ISO 9001 compliance is not just about ticking checkboxes. It’s about building systems that ensure product quality, minimize risk, and enhance customer satisfaction. COA automation plays a vital role in this ecosystem by transforming a traditionally manual, error-prone process into a streamlined, intelligent workflow—right within your QMS software.

If you’re aiming for tighter control, better traceability, and true ISO alignment, it’s time to explore COA automation as a strategic lever in your quality transformation journey.