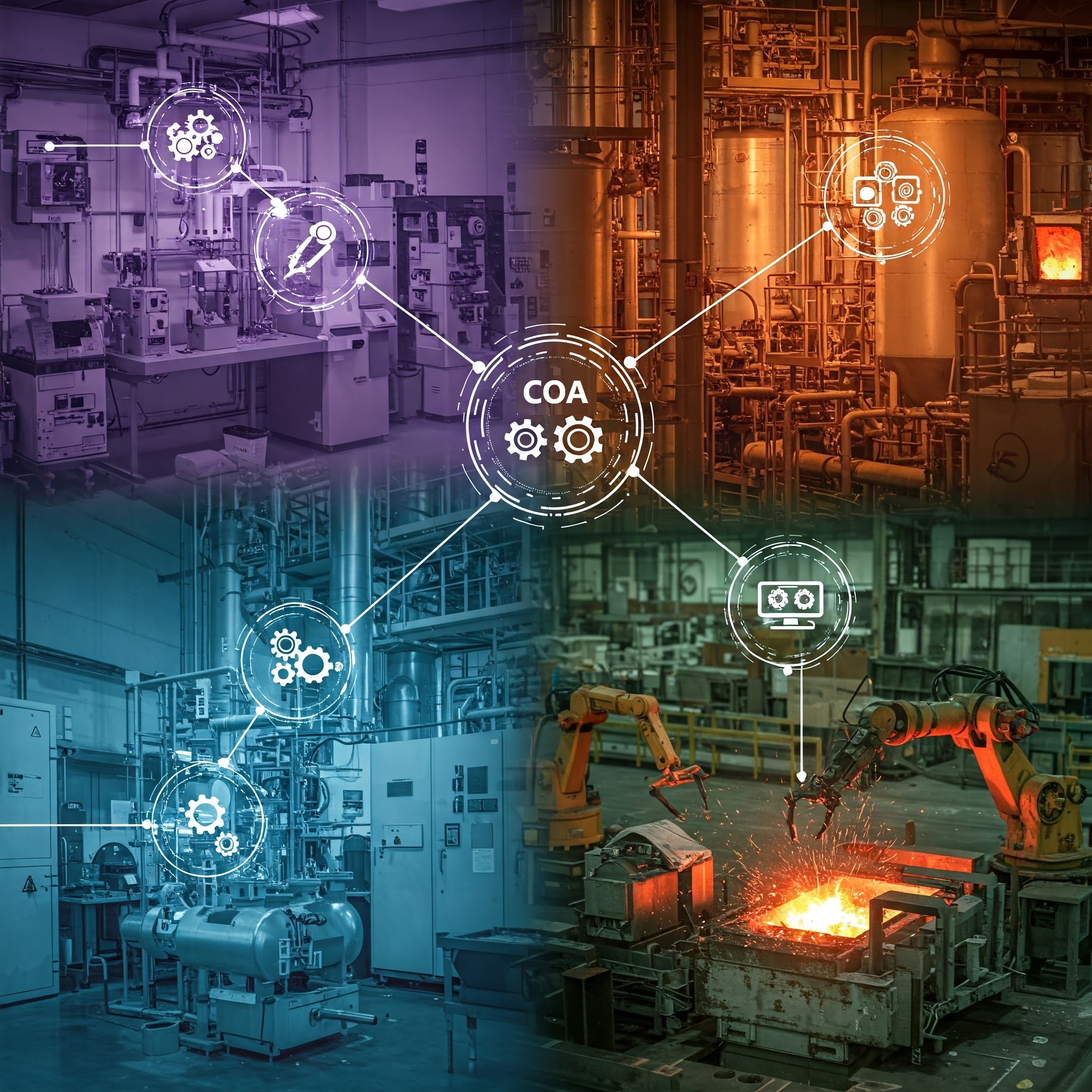

In highly regulated industries, Certificates of Analysis (CoAs) are not just routine paperwork — they are critical documents that ensure product quality, regulatory compliance, and customer trust. Industries like pharmaceuticals, chemicals, and metals each rely heavily on CoAs but face unique challenges in managing them. As companies increasingly adopt CoA automation, it’s clear that while the end goal — accuracy, speed, and compliance — is common, the journey looks different across sectors.

In this post, we explore the specific hurdles faced by these industries and the best practices they are developing as they automate CoA management.

The Pharma Industry: Precision, Traceability, and Regulatory Pressure

Challenges:

Zero margin for error: Even a minor mistake in a pharmaceutical CoA — such as incorrect potency data — can have life-or-death consequences.

Complex validation needs: FDA regulations (like 21 CFR Part 11) require validated systems and meticulous audit trails.

High data volume and granularity: Each batch may require CoAs for multiple parameters like identity, purity, sterility, and stability.

Best Practices:

System validation first: Pharma companies invest heavily in validating automation tools to meet regulatory expectations.

End-to-end digital audit trails: Automation platforms are configured to track every edit, approval, and access to CoA data.

Integration with LIMS (Laboratory Information Management Systems): Seamless integration ensures lab results directly feed into CoA generation without manual re-entry.

The Chemicals Industry: Speed, Variability, and Global Compliance

Challenges:

Wide product variations: Different chemical formulations require flexible, customizable CoA templates.

Regulatory differences across borders: Compliance requirements vary greatly (e.g., REACH in Europe, TSCA in the U.S.), complicating document standardization.

Shorter lead times: Chemical buyers often demand fast turnaround, putting pressure on CoA generation.

Best Practices:

Template-driven automation: Systems use dynamic templates that auto-adjust based on product type, destination country, and customer-specific requirements.

Multilingual support: Automated CoAs are configured to generate in different languages based on shipment locations.

Automated compliance checks: Built-in rule engines verify CoA content against country-specific regulations before dispatch.

The Metals Industry: Volume, Format Diversity, and Certification Authenticity

Challenges:

Massive documentation needs: Every coil, sheet, or bar of metal typically requires a dedicated CoA, creating overwhelming volumes.

Format inconsistencies: Suppliers, mills, and customers often use different CoA layouts and terminology.

Fraud risks: In high-value transactions, falsified CoAs can have major financial and reputational repercussions.

Best Practices:

Advanced OCR and AI extraction: Automation tools read and standardize CoAs from different suppliers into a common format.

Blockchain integration for authenticity: Some metals companies are experimenting with blockchain-backed CoAs to prevent tampering.

Customer self-service portals: Allowing customers to access CoAs directly via secure online platforms reduces administrative load and enhances transparency.

Key Lessons Across Industries

While each sector faces unique pressures, a few universal lessons stand out:

Prioritize data integrity: Automation must not compromise on data accuracy, validation, and traceability — especially in regulated environments.

Design for flexibility: Systems must handle product variations, customer-specific demands, and evolving compliance norms.

Drive integration: Linking CoA automation with broader systems like ERPs, LIMS, and CRM platforms ensures consistency and eliminates manual steps.

Plan for audits: Automation tools should make it easier, not harder, to respond to internal and external audits with complete, tamper-proof CoA records.

Automating CoA generation and management is becoming a competitive and compliance necessity across regulated industries. However, a one-size-fits-all approach doesn’t work. By learning from the experiences of sectors like pharma, chemicals, and metals, companies can implement smarter, more resilient CoA automation strategies that meet their industry’s specific demands while future-proofing their operations.

As the landscape continues to evolve, one thing is clear: those who invest early in CoA automation will be better equipped to deliver quality, speed, and trust in an increasingly demanding market.