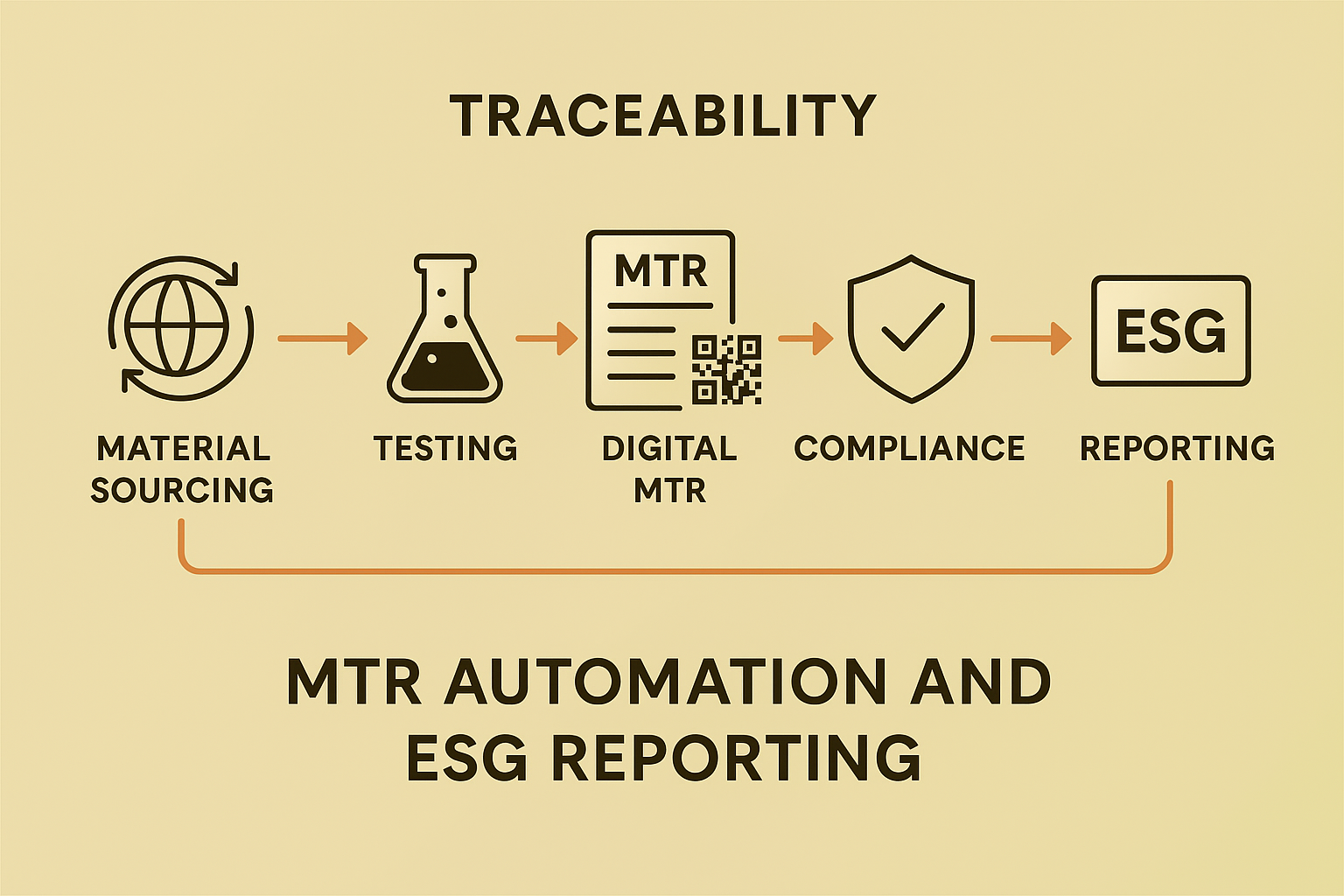

Sustainability reporting is only as strong as the data behind it. As industries embrace Environmental, Social, and Governance (ESG) goals and circular economy principles, the demand for transparency and traceability across the supply chain has never been higher. At the intersection of compliance, innovation, and sustainability lies a game-changer: automated Material Test Reports (MTRs).

What Are MTRs and Why Automate Them?

Material Test Reports document the chemical, mechanical, and physical properties of metals and other materials used in manufacturing. Traditionally handled manually, MTRs are essential for quality assurance and regulatory compliance—but they’re also ripe for transformation.

Automating MTRs with AI-driven document extraction, Optical Character Recognition (OCR), and system integration eliminates human error, accelerates reporting, and provides clean, structured data in real time. But beyond efficiency, this automation fuels deeper goals—especially around ESG reporting.

ESG Reporting Needs Reliable Data

Sustainability efforts are no longer optional. Companies are now required to disclose detailed environmental impacts, material sourcing, and production processes to regulators, investors, and stakeholders. Manually managing this data is time-consuming and prone to inconsistencies. Enter automated MTRs, which offer:

Accurate traceability of raw materials and suppliers

Instant access to compliance documentation

Streamlined audits for environmental certifications

Real-time updates for lifecycle tracking

With every material batch linked to a digital, tamper-proof trail, organizations can confidently back up their ESG claims.

Supporting the Circular Economy

The circular economy promotes using resources for as long as possible, extracting maximum value before recovery and regeneration. To make this work, manufacturers must know where materials come from, how they perform, and whether they can be reused or recycled safely.

Automated MTRs help close this loop by:

Tracking material lineage and quality from origin to end-use

Highlighting recyclable components or grades

Enabling predictive maintenance through material performance data

Reducing waste and overproduction through better inventory visibility

This isn’t just smart manufacturing—it’s responsible manufacturing.

Real-World Example: Metals and Mining

In the metals industry, ESG regulations are tightening, especially regarding carbon emissions and ethical sourcing. Companies using MTR automation are now able to:

Prove the origin of conflict-free materials

Validate the mechanical integrity of recycled steel

Benchmark emissions against global standards

These capabilities are helping companies not only reduce risk but enhance their sustainability ratings—a key factor in investor and customer decisions.

The Future: Integrating MTR Data into ESG Dashboards

Forward-thinking companies are already linking automated MTR data into ESG analytics dashboards, giving them:

Instant KPI tracking for sustainability goals

Alerts on material non-compliance

Visualizations for boardroom and stakeholder presentations

This integration brings ESG and quality assurance under one digital roof—driving smarter decisions and stronger compliance.

As ESG and circular economy pressures rise, automating MTRs goes from being a nice-to-have to a strategic necessity. By ensuring material traceability, quality, and transparency, MTR automation isn’t just about compliance—it’s about building a future where performance and responsibility go hand in hand.

Traceable materials lead to traceable impact. That’s the future of sustainable manufacturing.