Blogs, News & Articles

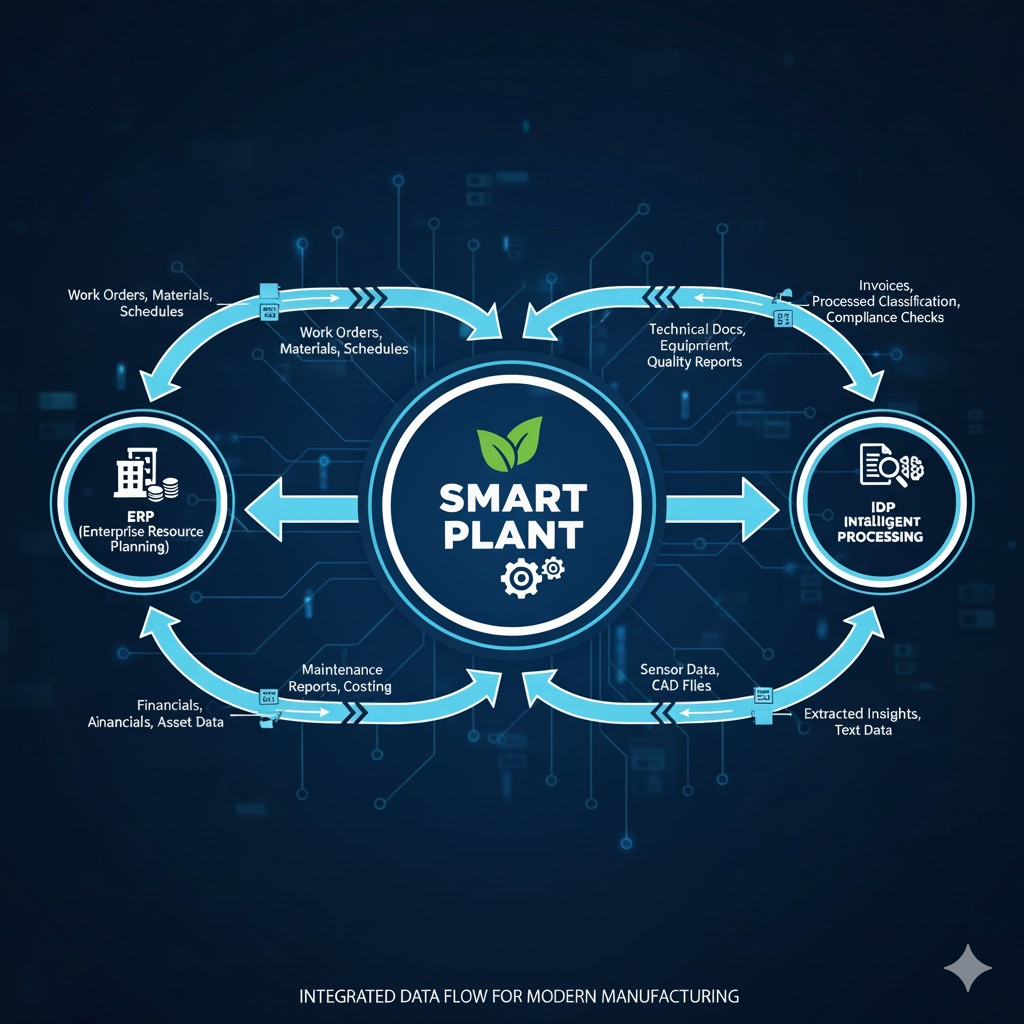

Why ERP–Smart Plant–IDP Integration Drives Industry 4.0

Industry 4.0 is revolutionizing how factories operate, bringing IoT, AI, and predictive analytics into daily workflows. Smart plants are already producing mountains of operational data—from equipment uptime to energy consumption and quality metrics. But the real value of this data emerges only when it is seamlessly integrated with financial systems inside ERP platforms.

Here’s the catch: before data even reaches ERP or smart-plant systems, it often originates in unstructured documents like invoices, supplier COAs, or MTRs. This is where Intelligent Document Processing (IDP) plays a vital role. Together, ERP, smart plant, and IDP automation form a closed-loop ecosystem that makes real-time decisioning possible.

Why Integration Across ERP, Smart Plant, and IDP Matters

Real-Time Cost Visibility

A smart plant can measure raw material usage per batch, but without ERP alignment you can’t translate that into real-time cost per unit. With IDP, supplier invoices and COAs are digitized, validated, and synced directly into ERP. The result: operations data combines with financial insights to deliver a true picture of profitability.Faster, Data-Driven Decisions

Market volatility—like aluminum price swings or pharmaceutical API shortages—demands instant responses. IDP ensures financial documents flow into ERP in near real-time, while the smart plant provides operational metrics. This combined data enables leaders to reallocate budgets, optimize sourcing, or shift production lines within hours, not weeks.Predictive Maintenance with Financial Context

IoT sensors may predict a pump failure in a steel plant. When this alert is linked with ERP and IDP-fed procurement data, managers can instantly weigh costs: is it cheaper to repair, replace, or reroute production? The decision is no longer just operational—it’s financially intelligent.Regulatory & Compliance Edge

Industries like pharma and metals face strict compliance standards. A COA scanned through IDP feeds quality and compliance data directly into ERP. Combined with operational logs from the smart plant, companies maintain a single, audit-ready system of truth, reducing compliance risks and manual reconciliations.

The Industry 4.0 Imperative

A 2023 Deloitte survey found that 73% of manufacturers are investing in tighter integration between ERP and plant-floor systems. Add IDP to the mix, and the benefits grow: McKinsey estimates that automated document processing reduces manual quality checks by up to 70%, freeing teams for higher-value tasks.

Another PwC report noted that manufacturers with ERP–operations–IDP integration achieved 15% EBITDA improvement through efficiency, agility, and compliance gains.

What Happens Without Integration

Finance teams rely on outdated, incomplete, or error-prone document data.

Operations make siloed decisions without financial context.

Compliance teams scramble to reconcile mismatched records.

Leaders lose agility when real-time pivots are needed most.

Smart plants without ERP, and ERP without IDP, are like engines running without dashboards—you’re moving fast but flying blind.

In Industry 4.0, ERP, smart plants, and IDP are not separate systems—they are three pillars of an intelligent enterprise. Together, they deliver real-time decisioning, financial clarity, and compliance confidence.

The future factory is not only automated—it’s data-driven, financially intelligent, and audit-ready. And that future depends on syncing ERP, smart plants, and IDP into one seamless ecosystem.

Why Data Accuracy Defines COA Automation in Pharma

In the pharmaceutical industry, where patient safety and regulatory compliance are paramount, Certificates of Analysis (COAs) are critical. These documents verify that raw materials, intermediates, and finished products meet predefined quality and safety standards. As companies adopt automation to streamline workflows, one truth stands out: in COA automation, the most critical step is ensuring data accuracy and integrity at the point of extraction.

Why Accuracy at Extraction Matters

Pharma COAs arrive in a wide variety of formats—PDFs, scanned images, or supplier-specific templates. Each document carries crucial details: assay results, impurity levels, dissolution rates, and compliance thresholds. A single misinterpretation—for example, reading “0.02%” as “0.2%”—can cascade into flawed validations, ERP mis-entries, or incorrect regulatory filings. The consequences can be severe: compliance breaches, costly recalls, or even risks to patient health.

A 2023 Deloitte survey revealed that up to 40% of pharma firms report compliance gaps directly tied to poor data capture in quality documentation. This proves that even the most advanced validation or integration systems cannot correct errors created at the extraction stage.

Regulatory and Client Expectations

Global regulators such as the FDA (21 CFR Part 11) and EMA place strict emphasis on data integrity, requiring pharmaceutical firms to prove that their records are authentic, consistent, and accurate. Any missteps in COA accuracy can result in FDA warning letters, production halts, or import bans.

Beyond regulators, clients demand error-free data as well. In tightly interlinked supply chains, a single inaccurate COA entry can delay drug release or shake trust. According to PwC, nearly 60% of pharma executives rank error-free quality data as the top factor in sustaining supplier-client relationships.

A Real-World Example: Novartis

Novartis, one of the world’s largest pharmaceutical companies, undertook a digital quality transformation initiative to strengthen its global supply chain. By implementing AI-driven document processing for COAs, Novartis was able to reduce manual quality checks by 65% and cut down review cycle times significantly. More importantly, automated extraction ensured accurate capture of assay and impurity data across thousands of supplier COAs. This allowed faster batch release, improved regulatory audit readiness, and created a single source of truth across their ERP and LIMS platforms.

Their experience illustrates how building accuracy at the point of extraction forms the foundation for efficiency, compliance, and trust. Without that foundation, downstream automation risks collapsing like a skyscraper built on weak ground.

The Payoff: Speed, Savings, and Safety

Accurate COA automation delivers multiple benefits. It reduces manual verification time by 50–70%, freeing skilled quality teams for higher-value work. It also minimizes human error, lowering the likelihood of recalls that, according to FDA estimates, cost $20 million to $100 million per incident. McKinsey further notes that pharma quality teams spend 25–30% of their time on manual document checks—time that automation can reclaim.

Ultimately, the integrity of COA data at extraction determines whether automation is a compliance liability or a competitive advantage. For pharmaceutical companies, the future of automation is not just about digitization—it is about building a foundation of trust, accuracy, and reliability from the very first data point.

AP Automation Across U.S. Heavy Metal Industries: Steel, Aluminum, and Glass

Accounts Payable (AP) departments across U.S. heavy metal industries—from steel to aluminum and glass—are under growing pressure to process rising invoice volumes, manage supplier diversity, and maintain compliance in a highly regulated environment. As companies modernize production with Industry 4.0 tools, back-office operations like AP are also shifting toward automation to ensure efficiency and resilience.

Steel: Managing High-Volume Supplier Networks

The U.S. steel industry, valued at over $120 billion annually, relies on thousands of suppliers for raw materials, transport, and equipment. Manual AP processes often delay payments, leading to strained supplier relationships. According to recent industry surveys, steel plants adopting AP automation have reduced invoice cycle times by up to 70%, cutting processing costs and improving on-time supplier payments. This is particularly critical as steelmakers face global competition and volatile raw material prices.

Aluminum: Tackling Compliance and Cost Pressures

For U.S. aluminum producers, AP automation is emerging as a solution to regulatory and compliance complexities. The industry is subject to tariffs, environmental reporting, and safety audits, making accurate and timely documentation essential. Automated AP systems ensure invoices are validated against purchase orders and compliance checks are completed before release. Companies that implemented AI-enabled invoice processing reported fewer compliance errors and significant cost savings, helping them stay competitive against imports from Canada and the Middle East.

Glass: Streamlining Cash Flow in Capital-Intensive Operations

The glass industry, which serves construction, automotive, and packaging sectors, operates with slim margins and high energy costs. AP automation helps manufacturers in this segment by offering real-time visibility into liabilities and cash flow. Automated three-way matching ensures that invoices align with purchase orders and goods receipts, reducing disputes with vendors. Some U.S. glass manufacturers are now leveraging predictive analytics within AP automation platforms to forecast payment schedules, optimizing working capital in an energy-sensitive market.

Why Now?

Fraud risks are also on the rise across all three sectors, with Business Email Compromise (BEC) and invoice fraud costing U.S. firms billions annually. AP automation platforms embedded with AI and anomaly detection safeguard against such threats, making them not only efficiency tools but also strategic shields against financial losses.

The Road Ahead

As heavy metal industries continue to integrate digital manufacturing technologies, AP automation will play a pivotal role in bridging operations and finance. Steel, aluminum, and glass producers that invest in intelligent AP platforms stand to gain faster invoice processing, better supplier trust, improved compliance, and stronger financial control. For industries where margins are tight and capital expenditures are high, the competitive edge lies not just in production efficiency but also in how seamlessly financial operations are run.

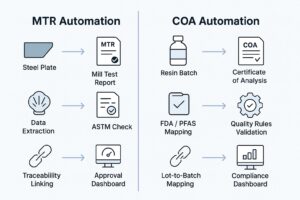

MTR vs. COA Automation: Star Software’s Differentiated Approach

Manufacturers across metals, chemicals, and plastics share one truth: documentation is as critical as the material itself. Two of the most important documents—Mill Test Reports (MTRs) and Certificates of Analysis (COAs)—may sound similar, but they differ in purpose, structure, and compliance implications.

Star Software takes a domain-specific approach, recognizing that a one-size-fits-all automation model won’t work. Here’s how the processes diverge—and why that matters for manufacturers in steel, aluminum, pharmaceuticals, and plastics.

MTR vs. COA: The Key Difference

MTR (Mill Test Report): Predominantly used in metals (steel, alloys, aluminum). It certifies chemical composition and mechanical properties as tested at the mill.

COA (Certificate of Analysis): Used across chemicals, plastics, pharma, and food industries. It certifies that a batch meets specific standards or regulatory limits.

In short:

MTR = Compliance with engineering standards (ASTM, ASME, ISO).

COA = Compliance with quality and safety standards (FDA, EPA, ISO, GMP).

Star Software’s Differentiated Automation Approach

1. MTR Automation Process Flow (Metals Industry)

Process Steps:

Document Capture → MTRs ingested from mills, suppliers, or OEMs (PDFs, scans, structured docs).

Data Extraction → Key fields parsed (heat number, grade, chemical composition, tensile, hardness).

Standards Matching → Automated mapping against ASTM/ASME standards.

Tolerance Validation → Checks for property ranges (e.g., carbon %, tensile strength).

Traceability Linking → Heat number linked to specific lots, purchase orders, and downstream products.

Compliance Report → Auto-generated compliance certificates for customers/regulators.

2. COA Automation Process Flow (Plastics/Pharma/Chemicals)

Process Steps:

Document Capture → COAs received from resin suppliers, labs, or pharma QA.

Data Extraction → Specs like melt flow index, density, additives, heavy metals, active ingredient % parsed.

Regulatory Mapping → Auto-check against FDA 21 CFR (food contact), GMP guidelines, EPA limits, PFAS bans.

Quality Rules Validation → Tolerance checks per SOP (± ranges for viscosity, assay results, microbial limits).

Lot-to-Batch Mapping → Batch-level traceability linked to finished goods.

Audit-Ready Dashboard → Packaged reports for FDA, EPA, or customer audits.

Chart: Comparing MTR vs. COA Automation

Feature MTR Automation (Metals) COA Automation (Plastics/Pharma) Industry Focus Steel, Aluminum, Alloys Plastics, Chemicals, Pharma, Food Key Data Heat number, chemical composition, tensile, hardness Melt flow index, assay %, additives, impurities Standards ASTM, ASME, ISO FDA 21 CFR, GMP, EPA, ISO, REACH Traceability Heat-to-lot, purchase order linkage Batch-to-finished product linkage Compliance Pressure Engineering & safety standards Regulatory, safety, and environmental norms Star’s Differentiation Heat-number based traceability graph Multi-regulatory rules engine + ESG reporting Why Star Software’s Approach Matters

No one-size-fits-all: A metals manufacturer needs ASTM compliance; a pharma plant needs FDA-ready dossiers. Star Software’s automation adapts to both.

End-to-end traceability: Heat numbers in metals or batch IDs in pharma—both are linked across ERP/QMS systems.

Audit readiness: Whether it’s a customer audit in aerospace metals or an FDA inspection in pharma plastics, compliance packs are generated instantly.

Sustainability edge: In plastics, COA automation supports PFAS bans and recyclability claims; in metals, MTR automation supports ESG-linked steel supply chain audits.

MTRs and COAs may seem like paperwork, but they are the passport of trust in manufacturing. By differentiating how each is automated, Star Software ensures accuracy, compliance, and efficiency across industries—helping U.S. manufacturers build not just stronger products, but also stronger reputations.

How COA Automation Helps U.S. Plastics Manufacturers Meet FDA, PFAS, and Recycling Norms

U.S. plastics is a heavyweight: $97.7B in GDP (NAICS 326) in 2023 and employs over 716K people as of July 2025. That scale makes every quality slip, non-compliance, or spec variance expensive—and environmentally costly. Automating Certificates of Analysis (COAs) is no longer back-office hygiene; it’s how resin producers, converters, and brand owners prove compliance, cut waste, and hit sustainability targets. FREDBureau of Labor Statistics

Why COAs Matter So Much in Plastics

Quality & Safety: COAs verify resin grade, MFI, density, additives, heavy metals, and migration compliance—foundational for FDA 21 CFR Part 177 food-contact applications. Automating intake/validation reduces manual error and speeds release-to-run. eCFRU.S. Food and Drug Administration

Regulatory Proof: COAs (plus attached test reports) provide the evidence trail for PFAS restrictions in packaging and evolving state EPR laws. In audits, “show me the paper” really means “show me the data.” U.S. Food and Drug AdministrationCalRecycle Home Pageepr.sustainablepackaging.org

The Compliance & Policy Backdrop (U.S.)

Food-contact plastics: FDA regulates the substances that can contact food (21 CFR 177). COAs confirm the polymer/additive system used is authorized and within limits. eCFRU.S. Food and Drug Administration

PFAS in packaging: FDA notes that as of Jan 2024 PFAS grease-proofers are no longer being sold into the U.S. market for food contact—brands still need supplier attestations/COAs to enforce this at scale. States are also enacting PFAS bans in packaging. U.S. Food and Drug AdministrationBCLP

EPR & recyclability (California SB 54): Producers must shift packaging to recyclable/compostable formats and hit 30% recycling by 2028, 65% by 2032, with fees tied to design impact. Accurate COA data (resin, additives, colorants) supports recyclability claims and fee calculations. CalRecycle Home Pageepr.sustainablepackaging.org

Market pressure: The U.S. Plastics Pact targets: 100% reusable/recyclable/compostable packaging and 30% recycled content by 2025—deadlines many firms are now sliding to 2030, but data demands remain. COAs are the primary, standardized feed for packaging material claims. U.S. Plastics PactThe Wall Street Journal

Sustainability & Pollution Control: Where COA Automation Pays Off

Less scrap, fewer purges: Automated COA checks (e.g., MFI ± tolerance, ash %, volatiles) before release prevent out-of-spec runs, cutting start-up scrap and purge waste.

Cleaner inventories: Systematic COA gating keeps restricted additives (e.g., PFAS, certain phthalates) out of BOMs, reducing the risk of off-spec lots entering production and later landfill.

Easier reporting: The EPA’s Toxics Release Inventory (TRI) increasingly scrutinizes plastics and additives (including PFAS). Digitized COA data streamlines annual disclosures and internal hotspot finding. In 2023, facilities reported managing ~1.56 million lbs of PFAS production-related waste—expect oversight to grow. US EPARegulations.gov

Circularity claims that stick: With <10% of U.S. plastic waste recycled, brands need defensible resin and recycled-content data to improve real outcomes (and avoid greenwashing). COA automation provides the audit trail for rPCR content and design-for-recycling choices. National Academies

What “Good” COA Automation Looks Like

Multi-format capture: Ingest supplier COAs from PDFs/portals/EDI; parse key specs (MFI, density, tensile, Vicat, additive IDs, batch/lot).

Rules & tolerance engine: Auto-validate against SOPs: grade-to-SKU mapping, tolerance bands, food-contact applicability (21 CFR section), PFAS-free attestations, colorant restrictions, recycled-content thresholds.

Supplier scorecards: Track first-pass acceptance, variance trends, late/missing COAs; trigger CAPAs.

Traceability chain: Link each finished lot back to resin lots, additive masterbatches, and their COAs for instant recall readiness.

Compliance dashboards: One-click dossiers for FDA food-contact, state PFAS packaging rules, CA SB 54 recyclability/readiness, and TRI support files. eCFRBCLPCalRecycle Home Pageepr.sustainablepackaging.orgUS EPA

Where to Start (Quick Wins by Segment)

Packaging (food & personal care): Enforce PFAS-free and 21 CFR 177 alignment; capture recycled-content COAs to substantiate label claims and meet retailer requirements. U.S. Food and Drug AdministrationeCFR

Medical & pharma plastics: Tighten biocompatibility inputs and lot-level test data; keep digitized trails for audits.

Automotive & durables: Standardize COA checks for thermal/mechanical specs to cut rework; map additives for DfR (design for recycling).

Resin producers & compounders: Provide machine-readable COAs (JSON/CSV) with batch analytics to reduce downstream NCRs and bolster service levels.

How Star Software Helps

Star Software automates the COA lifecycle for plastics manufacturers and brand owners:

Intelligent ingestion: Reads multi-vendor COAs (scans, structured PDFs, spreadsheets) and normalizes fields like resin family, MFI, density, tensile, colorant IDs, RoHS/REACH flags.

Policy checks: Applies your FDA 21 CFR 177 mapping, PFAS-free attestations, and SB 54 recyclability logic to approve/hold lots automatically.

Traceability graph: Links raw-material COAs to WIP/FG lots for instant backward/forward tracing.

Audit & reporting: Generates binder-ready compliance packs for customers and regulators; exports data to ERP/QMS/LIMS.